If you would like to have a new floor added to your garage, there are a couple of primary options available to you today. One option is a traditional epoxy floor, a choice that has been used by many home and business owners. Alternatively, you may opt for a polyaspartic floor, such as those offered by Ohio Garage Interiors.

While many consumers confuse these as being essentially the same thing, they are actually different products with different performance characteristics. Polyaspartic delivers a more durable, lasting solution for your garage floor, which is why it is the product we install for our customers. Epoxy can work fine for a while, but it will start to show signs of wear and tear sooner rather than later, and you may find yourself back in the market for another flooring solution. Going with polyaspartic from the start will save that hassle – and additional expense – and leave you with a floor that is going to serve you nicely for years.

Generally speaking, the installation process for an epoxy garage floor is going to last for just a single day. That might seem like a selling point, as the work will be done quickly, but there is a trade-off for that speed that you might not want to make in the end. More on that later.

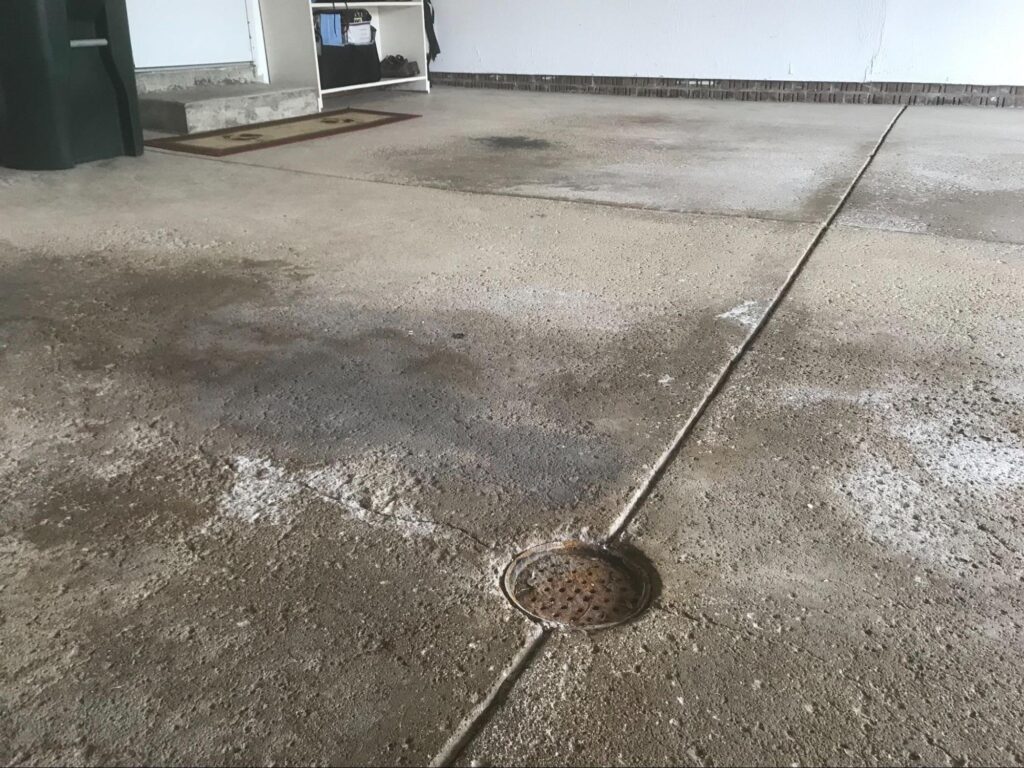

For now, the installation process is going to start by preparing the surface of the garage floor to receive an epoxy coating. Surface prep can include carefully cleaning the entire area to get rid of any dirt, oil, grease, or anything else that might get in the way of a solid bond between the concrete and the epoxy. Also, diamond grinding can be used to create some texture and give the epoxy a better chance to adhere firmly.

The Two-Day Installation Process for a Polyaspartic Garage Floor

The process of installing an epoxy garage floor is pretty simple, and in many ways, installing a polyaspartic garage floor will follow similar steps. Again, we’ll get started by cleaning out the garage, cleaning the floor, and using diamond grinding to get the surface ready to go. A basecoat is then applied, to which vinyl flakes will be added to provide a nice aesthetic.

Trust the Right Team for the Best Results

By going with polyaspartic for your garage floor, you will be making a choice that is going to serve you well in both the short- and long term. However, just picking polyaspartic over epoxy isn’t the end of the story – you also have to pick an installer.