Are you thinking of new floors for your garage or business? If you’ve looked online for solutions and tips, you’re bound to run into a lot of bold claims, questionable advice, and YouTube “experts” who make every coating look simple.

Some information out there is accurate, but the keyword is “some.” In truth, there’s a good chance that you’re seeing the most common garage flooring myths.

Fall for any of them, and you might opt for hasty fixes out of panic and disinformation.

Here are some of the most widely held garage flooring myths that are more fictional than factual.

Myth 1: Epoxy Is Cheaper, So It Is Automatically the Better Option

A lower price tag can be tempting, but it does not tell the whole story.

Epoxy coatings often cost less upfront because the material itself is an older technology. It cures slowly, it is more sensitive to humidity, and struggles with long-term UV exposure. You may save money on the initial install and spend more later on repairs, discoloration, or a full replacement.

Polyaspartic coatings typically cost more because the chemistry is more advanced. They cure faster, bond more reliably, and resist peeling and delamination when installed correctly. They also hold up better to sunlight, which helps prevent fading.

While epoxy can work in some environments, the “cheaper equals better” idea falls apart once you factor in longevity, durability, and the cost of future fixes.

Myth 2: All Garage Floor Coatings Perform the Same Way

Coatings look similar on the surface, but their performance varies widely. Epoxy, polyurea, and polyaspartic systems each behave differently once they hit concrete.

Epoxy is rigid, making it vulnerable in a garage where temperature changes cause concrete to expand and contract. It can crack or chip over time, especially in climates with freeze-and-thaw patterns.

Polyaspartic coatings have more flexibility and stronger chemical resistance. They tolerate extreme temperatures, dropped tools, and routine abrasion significantly better. When properly installed, they penetrate the concrete and create a strong mechanical bond that helps prevent peeling.

If all coatings performed the same way, you would not see professional installers replacing failed epoxy floors as often as they do.

Myth 3: DIY Kits Give You the Same Results as Professional Installation

DIY kits promise convenience, but they leave out the most important part of the process, which is the surface preparation. A roller and a box of epoxy cannot fix concrete that has moisture issues, existing coatings, cracks, pitting, or uneven texture.

Professionals use mechanical grinders equipped with diamond tooling to open the pores of the concrete. This ensures that the coating seeps in and adheres properly. DIY acid etching does not achieve the same effect. It may clean the surface, but it does not give the coating a consistent surface profile to grip.

DIY kits can leave you with hot tire pickup, peeling patches or rough spots that do not cure evenly. When that happens, you either live with the mistakes or pay for a full removal and redo. In many cases, the “easy DIY route” becomes the more expensive mistake.

Myth 4: A One-Day Installation Is Just as Good as a Two-Day Process

Some companies advertise one-day garage floor installation to attract homeowners who want a fast turnaround. The idea sounds great, but it skips over important steps.

Concrete needs time to be prepared correctly. Grinding, repairing cracks, patching pits, and applying the first coat all take time. Polyaspartic coatings cure quickly, but the floor still needs a proper window to bond, settle, and build long-term strength.

A two-day installation allows each layer to cure at the rate it needs. Rushing the process can leave you with weak bonding, thin spots or early wear in high-traffic areas.

A garage floor is something you want done once and correctly. A little patience goes a long way when it comes to durability.

Myth 5: Garage Floors Do Not Need UV Stability

Sunlight matters more than you may think. Many garages have windows, open doors or partial exposure that allows UV rays to hit the floor. Epoxy tends to become amber or yellow over time when exposed to sunlight.

Polyaspartic coatings are UV-stable, which means they maintain their color and finish even in brighter garages. If you want a floor that looks just as good two years from now as it does on installation day, UV stability is essential, not optional.

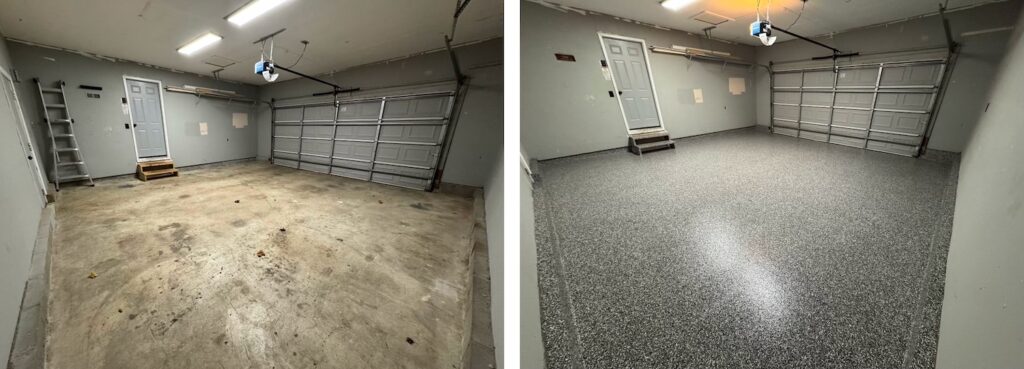

Flooring Facts and Functional Fixes With Ohio Garage Interiors

If you want a garage floor that stands up to daily life and looks good doing it, the process matters as much as the product. OGI installs polyaspartic floors using a two-day system that gives your concrete the prep, repair, and curing time it needs. This helps your floor last longer and look better through every season.

If you are ready for a garage floor that feels solid, looks polished, and holds up to actual use, our team is here to help.

Book a free on-site consultation and see what a properly installed polyaspartic system can do for your home.