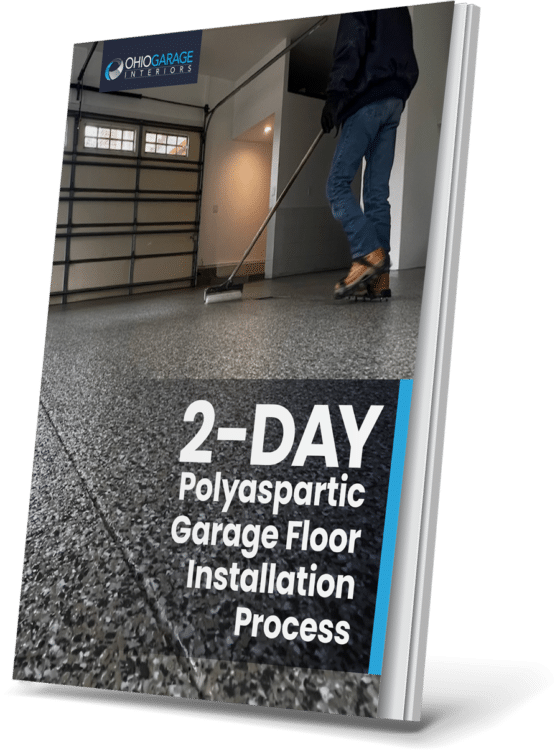

Get a Durable, Long-Lasting Polyaspartic Garage Floor in Just Two Days

Ohio Garage Interiors uses a two-day installation process to create durable, attractive garage floors for our customers. Is it possible to install a polyaspartic coating system in a single day? Yes, but we don’t think that’s the right way to do it.

Keep reading to explore our two-day process and learn why it yields a superior finished product.

The Benefit Behind a Two-Day Process

When working with materials like polyaspartic, curing time is everything. When the job is rushed and completed in just a single day, curing time is sacrificed, and so is the quality of the finished product. We are proud to use a two-day process specifically because it allows the coatings to cure thoroughly.

Give us two days to install your polyaspartic garage floor and you will love the results for thousands of days ahead.

Two-Day Process Overview

BEFORE

Before: Getting Ready for the Job

Once the job is scheduled, the first step in the process is for you to thoroughly clear out your garage in advance of the project. This could take an hour or an entire weekend depending on how much stuff you have in your garage, so plan accordingly so you have enough time before the start of the job.

Planning to decide where you will move and store all your items during the project will help make the cleanout process much more manageable. In addition, you can take this opportunity to establish an organizational structure for the items in your garage that you can carry over into your freshly updated space.

DURING

A Thorough, Detailed Process

With the garage cleared, it’s then time for our experts to get to work. The process of installing a new coating system in your garage follows the general steps below:

Concrete Prep – A mechanical diamond grinding process is used to roughen the surface and prepare it to bind firmly with the polymer coating.

Basecoat – The first layer of high-quality epoxy primer is poured, spread throughout the garage with a squeegee and then rolled even.

Flakes – Decorative flakes are spread over the surface while the coatings are still wet. The next day, the flakes that didn’t adhere to the basecoat are scraped, broomed and vacuumed.

Overnight Curing – The floor is left to cure overnight.

Finish Coat – A polyaspartic topcoat is applied over the flakes and grit is applied for texture.

AFTER

Curing & Ready for Use

Final Cure – After a day or two of letting the floor fully cure, it’s ready to use!

Lifetime of Enjoyment – At this point, the installation of your new garage floor coating system is complete and you can begin to use it. That storage system you may have established while clearing out your garage will now come in handy!

ALWAYS

A Wise Investment

When you get a new polyaspartic garage floor coating system installed by Ohio Garage Interiors, that work is backed by a 20-year warranty. Love it today, love it in 20 years. You’ll always have the peace of mind that you made a wise investment in your home.