Restore and Protect Your Garage Flooring with Ohio Garage Interiors

Ohio’s weather is infamously turbulent and unpredictable, so unprotected garage floors crack more quickly than in other climates. The typical concrete slab in an Ohio garage will need to withstand frequent temperature and humidity fluctuations as well as winter thaw cycles. As a result, concrete flooring will shrink, expand, and crack. OGI’s garage flooring experts can fill the cracks in your flooring and protect it from damage with high-performance epoxy.

Looking to repair cracked concrete garage floor in Ohio but not ready to commit to services? Schedule a free in-home inspection with us today! One of our expert flooring contractors will inspect your current flooring and provide you with a free quote. We also accept photos of flooring if you do not have time for an on-site inspection.

The process to repair cracked concrete garage floor

If you see cracks forming on your floor, it is best to treat them as soon as possible even if they are small cracks. We have the experience and tools necessary for precision crack repairs and epoxy coating installations, so we can restore and protect your concrete flooring.

Recommended materials for crack repair

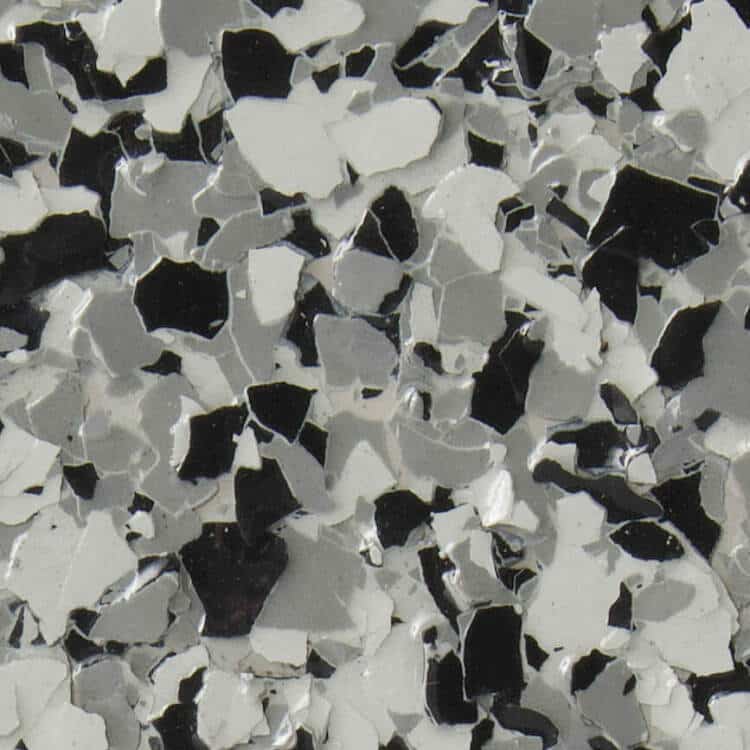

There are many concrete crack filler products and repair materials on the market. However. if you want to perform the highest quality repairs, polyaspartic epoxy is the ideal solution. In fact, polyaspartic garage flooring epoxy is an OGI specialty.

We have designed our flooring systems specifically for the Ohio garage environment, so they can offer superior protection and longevity. Our polyaspartic coating systems are made with polyaspartic polyurea. As a result, they can defend concrete flooring from any incoming hazards including dirt, dust, mold, mildew, flooding, road salts, corrosive chemicals, and more! Furthermore, our polyaspartic epoxy contains a crack filler compound to optimize flooring repairs.

Steps for crack repair

We begin crack repair by chasing cracks with a hammer and cold chisel. We position the chisel in the crack and hit it with a hammer, breaking off any loose debris. Then, we clean the debris with a wire brush and vacuum out the cracks.

After we complete the initial crack repairs, we will grind and sand your flooring until smooth. This will improve the effectiveness of our polyaspartic epoxy application. Most importantly, our polyaspartic coatings will fill the cracks, protect the underlying concrete, and give your floor a stylish new finish.

Want the best in garage polyaspartic flooring?

Talk to the best garage polyaspartic companies near me.

Polyaspartic floor coating installation cost

Ohio Garage Interiors proudly offers both the highest quality and value for garage flooring installation and repair services in Northeast Ohio. In your search for crack repair services in Ohio, you have likely found numerous businesses offering speedy, one-day flooring installations. For many homeowners, this would seem like a convenience you simply cannot pass up. However, one-day installations are not only rushed and imprecise, but they also cost $3 more per square foot on average.

As a result, you will receive subpar garage flooring that quickly forms many troublesome defects. This will cost you even more money with expensive repairs and maintenance that could have been avoided. With OGI, however, you will not have to worry about defects and repairs. We perform thorough, two-day installations, so our polyaspartic epoxy can properly cure and form the strongest bond possible with your concrete garage floor.

We start our garage flooring repair and installation services at $6.95 per square foot, but we also have many discounts for projects in garages that meet or exceed 600 square feet. So, you can perform the repairs you need and install new flooring without overspending. Here is an example of our discounts:

- 600 sq ft or more – 10% Discount on Price of flooring

- 900 sq ft – 15% Discount on Price of flooring

- 1,200 sq ft – 20% Discount on Price of flooring

- 2,500 sq ft – 25% Discount on Price of flooring

*A minimum project size of $3,000 is required.

Ohio Garage Interiors | Repair Cracked Concrete Garage Floor

Looking for garage flooring crack repair or installation services in Northeast Ohio? Get in touch with Ohio Garage Interiors today! We perform all our garage flooring year-round, so do not hesitate to contact us and schedule an in-home inspection for a free quote.