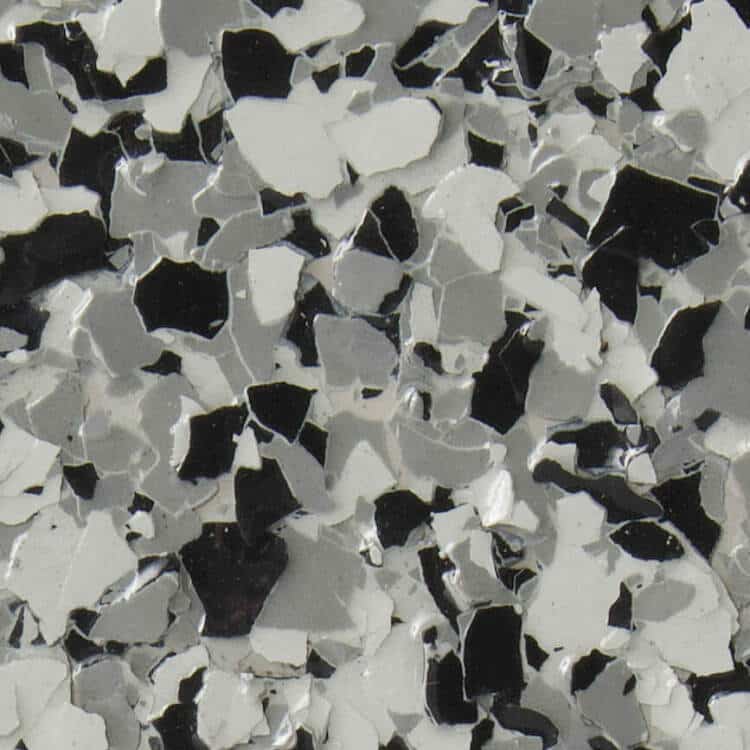

What type of garage flooring does OGI apply? Garage epoxy paint? DIY epoxy?

No, our high-quality epoxy flooring for garage floors are a resinous hybrid polymer garage floor coating system. OGI garage flooring is a 3-layer system consisting of high-grade epoxy basecoat primer, a broadcasted polymer flake layer and a Polyaspartic Polyurea clear topcoat. Our floor coating system is also stain-resistant and easy to clean with five times the strength and flexibility of standard epoxy. Unlike inferior DIY epoxy systems that degrade and peel, OGI coatings create a permanent bond with the concrete for ultimate durability. Furthermore, OGI garage flooring products are both UV stable, which prevents yellowing and environmentally friendly with low volatile organic compounds (VOCs). There is a slight solvent smell to our topcoat. However, it will dissipate within 24 hours.

How thick is the floor?

The total OGI system is about 30 mils thick, which is about the thickness of a credit card.

How does OGI prepare the concrete?

When first poured, garage concrete is always finished to create a smooth and even surface. The finishing process reduces the overall porosity. As a result, the surface must be profiled to expose the pores for effective polymer bonding. Prepping a concrete floor for coating is the most crucial step of a successful installation. If not performed properly, the coating will fail to provide the protection your flooring needs. Typically, etching and pore exposure is performed by mechanically grinding the surface or acid etching, but which method is better? The best method for profiling concrete for hybrid polymer floor coatings is to mechanically grind the surface with diamond pattern tooling. It creates a deeper texture profile, so the coatings will adhere properly.

Is it a stone and epoxy product?

No. We often receive questions about whether our coating is a stone and epoxy product. However, there are quite a few differences between a stone and epoxy product and a hybrid polymer epoxy. Firstly, rather than using stone for our coatings, OGI flooring consists of broadcasted polymer flakes. Our coatings are also thinner than stone and epoxy products and do not affect the height of your flooring. Most notably, our coatings are non-porous while stone and epoxy products are inherently porous. As a result, our coatings will seal the concrete and protect it from harmful substances such as salt residue. It is crucial to prevent these substances from dissipating into a porous surface like stone and epoxy products. Stone and epoxy flooring allows saltwater, gasoline, oil, pet urine, etc. to penetrate the flooring and get trapped underneath. Annual steaming maintenance is a necessity for cleaning stone and epoxy flooring. However, OGI coatings require no continual maintenance other than the occasional hosing off. Therefore, you save far more money in the long run with epoxy coatings than stone and epoxy flooring.

What’s the difference between you and a stone and epoxy product?

Stone and Epoxy is a porous floor that is made up of actual stone. OGI flooring is a non-porous hybrid polymer epoxy floor that requires low maintenance. OGI is also a family-owned, local business, with a no-pressure consultation.

How does OGI repair the cracks and pitting in concrete?

Over time, garage flooring begins to break down from years of salt exposure from vehicles and various other harmful substances. This results in deep pitting in the concrete’s surface. Prior to applying our floor coatings, we repair any damage with a high-grade, self-leveling polymer, which fills in all pitting and cracks. We then grind the surface until it is smooth and apply our coating system.

Does OGI fill in Expansion/Control Joints?

When coating a garage floor, some will want to fill the joints entirely, so they can have a floor with a seamless aesthetic. However, we do not believe it is advisable to do so. These joints are the deep cut grooves that run from one end of your garage floor to the other. Concrete expands and contracts with temperature and also moves as the underlying earth settles, which results in cracking. Contraction joints play an integral role in preventing cracks from running across the slab. They create a weakened line in the concrete, which redirects cracks to run within the joints. We recommend filling the joints about halfway with a flexible sealant, which allows concrete movement and prevents dirt from getting compacted in the gap.

Can OGI re-grade the pitch of the concrete or fill in low settled areas?

Unfortunately, OGI coatings are relatively thin, so they do not allow us to re-grade the pitch of the concrete flooring. Our coatings will cover the existing concrete, in which we can only make small modifications to the original slab such as repairing cracks and pitting.

How long with the coating last? Do I need to have it resealed?

OGI polymer floor coatings typically last between 15 and 20 years before potentially needing an additional clear coat.

What kind of warranty does OGI provide?

We offer a 20-year warranty against peeling and delamination with no required maintenance program.

How slippery is the epoxy flooring for garage floors?

The aggregate and vinyl flakes added to the floor to provide slip resistance.

Does the floor become slippery when wet?

We recommend using slip-resistant aggregates in all floor coating systems. These aggregates can be incorporated into the clear coat finish with different methods to achieve varying profiles and degrees of slip resistance. Factors to consider when deciding on the degree of slip resistance include the type of activity on the flooring surface, maintenance procedures, type of footwear and more. OGI’s slip-resistant aggregate is aluminum oxide.

How do you clean the garage floor epoxy coatings?

For minor spills or vehicle drippings, simply wipe them up with a paper towel or soft cloth. Routine maintenance is most effective with a soft bristle broom or a commercial dust mop, which are available at any home improvement store. For heavy cleaning, sweep away any loose debris and mop the floor with a string mop with water and CLEAR ammonia. Six ounces of ammonia per gallon of water are all that is necessary for adequately removing soiling. The floor can be hosed out and squeegeed or even lightly power washed. For more soiled floors or stubborn oil marks, a degreaser from a home improvement store is effective. Try a diluted mixture and increase the dilution ratio as needed. Make sure to rinse with water after the solution sits for about 15 minutes and repeat if necessary. Try not to use any cleaner containing solvents, acids (citrus cleaners, vinegar, etc.) or soap-based cleaners. Soap-based cleaners can leave a residue on the floor that not only detracts from the shine but also becomes increasingly slippery should the floor get wet.

Do I need to replace my drain cover?

OGI includes the option to either refurbish or replace your drain cover in our floor coating service. This is typically dependent on the condition of the existing drain cover. If possible, we will repair and coat the drain cover for a new look and extended lifespan and utility. When refurbishing is not an option, we will size and replace your drain cover with a new, durable polypropylene cover. We strive to give your completed garage floor a sharp and cohesive design, including your drains.

Will the floor coating adhere to vertical surfaces such as steps or foundation walls?

Yes, we can absolutely coat steps and foundation walls. We can coat these vertical surfaces as we coat your floor, so you are left with a completely sealed, seamless coating.

What is the cost for a standard 2 car garage?

We are priced by square foot. A garage this size usually falls in the price range of $2900-3100.

What is the actual garage flooring made of?

The floor has an epoxy base with a vinyl flake coating and is sealed with a Polyaspartic topcoat resin.

How long does it take to do the floor, when can I use the garage again?

The floor application is a two-day process, with a 48-hour dry time.

Do you provide storage or move days the items from the garage?

We do not provide a portable storage unit; however, we can refer you to a vendors list. It is the responsibility of the homeowner to make sure the garage is clear on the day of installation.

How long does the estimate take?

Depending on the size of the area you would like coated, estimates can take 30-60 minutes.

What is the lead time for installation?

It depends on the time of the year. During our busy season, there could be a 6-8 week wait for install.

Can you give us a quote for our patio or basement as well?

Unfortunately, we no longer provide estimates for exterior surfaces. We can look at the basement while we are at the property and advise from there.