Garage Floor Replacement

There are many issues that can lead to a garage flooring replacement, so it is important to keep an eye out for any serious damages or defects.

Common Issues for Garage Floor Concrete | Garage Floor Replacement

Cracking and Pitting

Garage flooring concrete is naturally rigid, so cracks are inevitable for any bare concrete floor. Concrete will also expand and shrink with humidity and experience thaw cycles during the winter months. These are two leading causes of cracking in concrete flooring.

Minor cracking is only a surface level issue, so repairing it is a quick and simple process. OGI’s team of garage floor replacement contractors can repair any cracking and protect your flooring from any further damage.

Contraction and control joints are another common cause of cracking. These joints exist to lead cracks down a preset path, so they do not cause cracking across the entire concrete floor. However, they do cause more frequent cracking on individual slab sections of the flooring.

If you notice any major cracks that are 1/4-inch or larger, the repair process is a bit more involved. OGI will need to grind and fill these cracks prior to performing the garage floor replacement and installation polyaspartic epoxy. We will chase these cracks with a cold chisel and hammer or masonry wheel, so we can apply the crack fillers and install the polyaspartic epoxy effectively and prevent any further damage.

When you start noticing cracks and pitting in your garage flooring, it is best to repair it sooner rather than later. Contact OGI today to start planning your garage floor replacement.

Minor and Major Settling

In cases of minor settling, we can correct this issue with a quick application of self-leveling concrete. Major settling, however, can result in a full garage floor replacement. If you think you might need to replace your flooring, always contact a contractor and ask for a quote before committing to a service.

OGI offers a wide variety of garage flooring repair services, so you may be able to avoid a full replacement. We also offer free quotes with every in-home inspection.

Once you get quotes for both of these procedures, compare the pricing. If the repairs are nearly the same price as a replacement, it is best to go with the replacement procedure.

Want the best in garage polyaspartic flooring?

Talk to the best garage polyaspartic companies near me.

Garage Floor Replacement Process | Garage Flooring Installation

Prepping and Grinding the Concrete

Preparation of the garage flooring concrete is the most crucial part of the garage floor replacement process. OGI’s team of flooring installation experts will inspect the current flooring, recording density, damages and other important aspects. As a result, we can determine the most effective method for repairing the concrete and performing the garage floor replacement.

Our process involves prepping the concrete with diamond grinding, which scarifies and etches the floor with diamond segments. This opens the concrete’s pores, so the polyaspartic epoxy can properly bond to the substrate.

Prepping the concrete also involves repairing and cracking or spalling. Hairline cracks will be opened with a diamond grinder and filled with polyurea concrete filler. We will then grind any remaining filler and smooth the concrete before installing polyaspartic epoxy.

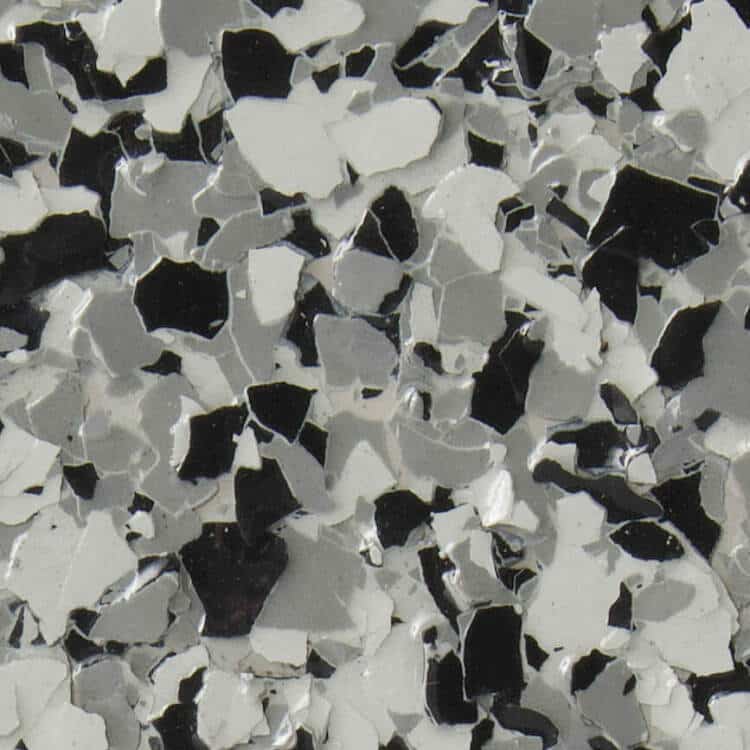

Basecoat and Decorative Flake Application

The basecoat of OGI flooring consists of a high-grade polyaspartic epoxy primer layer. We flood the flooring with this coating and squeegee it around the room. Then, we back roll then materials, so we can even out the surface and apply decorative flakes.

We can also apply basecoats and decorative flakes to vertical surfaces in your garage. These materials need to cure overnight, so we can ensure a stronger bond with the existing concrete and more long term durability. Once the basecoat finishes curing, we will remove any remaining flakes and clear the floor of debris.

Topcoat Application

The final step of garage floor replacement is the topcoat. OGI applies topcoats with the most advanced polyaspartic epoxy products in the residential garage flooring industry. This epoxy is made of polyaspartic polyurea.

As a result, it provides exceptional adhesion and durability properties. Once we apply the clear coat, it will need 24 hours to cure before residents can travel over it. As for vehicles, they can enter the garage after roughly 36 to 48 hours.