Epoxy Floor Coating Process | Garage Flooring Installation

Prepping and Grinding the Concrete

The preparation of the concrete floor is the most important aspect of the garage floor coating process. Our team of expert contractors will analyze your current garage flooring, taking note of its density, visible damages and any other relevant characteristics. As a result, we will be able to determine the best course of action for repairing the concrete and installing the polyaspartic epoxy garage floor coating.

Here at Ohio Garage Interiors, we prep the concrete with a process of mechanical diamond grinding. This process involves scarifying or etching the concrete with diamond segments, opening the pores of the concrete and allowing the coating to soak in and bind properly to the substrate.

Preparation also involves the repairing of any cracking, pitting or spalling from extended exposure to environmental hazards such as road salt. For issues such as hairline cracks, we can open them up with the diamond grinder and fill them with a polyurea concrete filler. We will grind any excess filler and smooth out the concrete surface before applying the polyaspartic epoxy.

Once the concrete is smooth, we will vacuum the flooring and remove any dust or debris left behind during the grinding process.

Basecoat and Decorative Flake Application

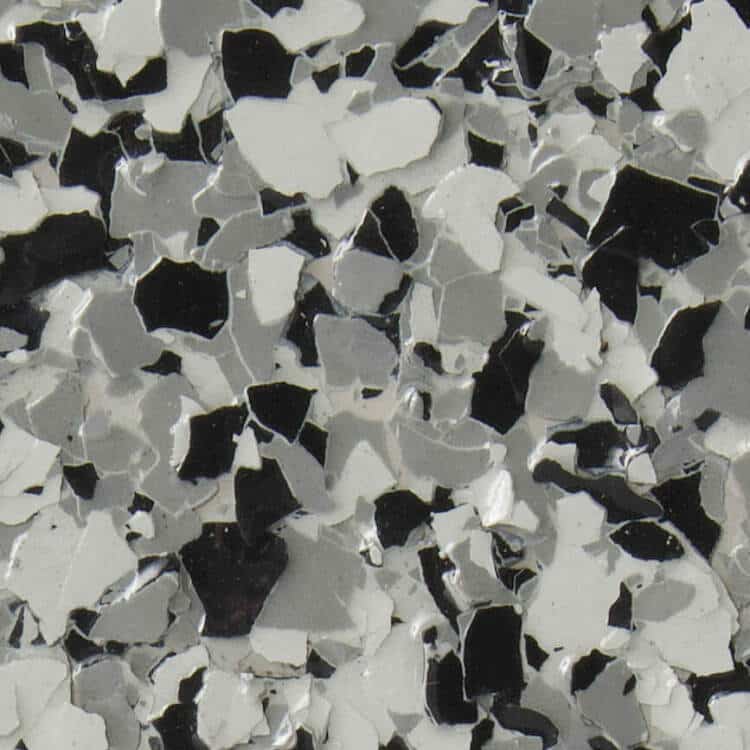

Our basecoat process involves applying a high-grade polyaspartic epoxy primer layer. We flood coat the flooring with the polyaspartic epoxy and squeegee it across the room. Then, we back roll to even out the materials and begin applying decorative flakes while the floor is still wet.

We also apply the basecoat and flakes to any vertical surfaces. The basecoat and decorative flakes need to cure overnight. As a result, we can ensure a stronger bond the concrete and higher durability. Once the basecoat cures, we vacuum the excess flakes and clean the floor to remove any remaining debris.

Topcoat Application

Ohio Garage Interiors uses the most advanced topcoat epoxy product in the residential flooring installation industry. Our topcoat epoxy consists of polyaspartic polyurea, so it offers better adhesion and durability. After applying the clear coat, it needs 24 hours to cure before you can walk on it. It will be ready for vehicle traffic within 36 to 48 hours.

Frequently Asked Questions

What type of garage flooring does OGI install? Garage epoxy paint? DIY epoxy?

No, our garage flooring is a resinous hybrid polymer epoxy coating system. OGI flooring is a 3-layer system with high-grade polyaspartic epoxy basecoat primer, a broadcasted decorative flake layer and a topcoat of Polyaspartic Polyurea clear. Our polyaspartic epoxy coating system is also stain-resistant, so it is easy to clean. Furthermore, it offers five times the strength and flexibility of standard epoxy.

Other epoxy systems degrade and peel, OGI polyaspartic epoxy forms a permanent bond with the concrete flooring for maximum durability. OGI garage flooring, however, is UV stable and has low volatile organic compound (VOCs) compound, so it prevents yellowing and is environmentally friendly. There is a slight solvent smell to our topcoat. However, it will dissipate within 24 hours.

How thick is the flooring?

The OGI system is approximately 30 mils thick or about the thickness of a credit card.

How long will the polyaspartic epoxy last? Do I need to have it resealed?

OGI polymer coatings last between about 15 and 20 years before possibly needing another clear coat.

What kind of warranty does OGI offer?

We offer a 20-year warranty against peeling and delamination requiring no maintenance programs.

Will the floor coating adhere to vertical surfaces such as steps or foundation walls?

Yes, we can coat both steps and foundation walls. We will apply the system to vertical surfaces as we coat the floor, so you receive a sealed, seamless coating.

What is the cost of a standard 2 car garage?

We price the flooring by the square foot. A 2 car garage usually falls between $2900 and $3100.

What is the flooring made of?

The flooring has an epoxy base, a vinyl flake decorative coating and a sealed with Polyaspartic Polyurea topcoat resin.

How long does the installation take, when can I use my garage again?

Installation is a two-day process, with 48-hour dry time.

Do you provide storage or moving for the items in the garage?

We do not offer a portable storage unit. However, we can provide you with a vendor list. It is the homeowner’s responsibility to clear the garage and find storage for belongings prior to the day of installation.

How long does the estimate take?

Depending on the size of the area garage, estimates take about 30-60 minutes.

What is the lead time?

During our busier season, there could be a wait of 6-8. It depends on what time of year.

Can you give us a quote for our patio or basement as well?

We no longer provide estimates for the exterior of the home. However, we can look at the basement during the inspection and advise you from there.